How NOT to Ruin Your Fly Line May 13, 2021 – Posted in: Fly Casting, Instruction – Tags: fly fish, fly fishing, fly line, fly line casting, fly reel, fly rod, flyfish, flyfishing, flyline, Scientific Anglers

So, you just got a new fly line and can’t wait to try it out. You don’t have time to run over to your local stream or pond, so you’ll just give a try on your lawn, that’s OK, right? Well, it really is not a good idea. In fact, it is a really bad idea. A session of lawn casting can actually ruin that shiny new, hi-tech fly line you just shelled out a cool, $100.00 plus for. Let’s take a look at some of the things that can really do damage to a fly line before you even step into the water.

Just to be clear, this is not a PSA on how to maintain your fly line. There are a ton of videos and articles to reference for that. Instead, this is a guide on how not to ruin your fly line. At Scientific Anglers, we pride ourselves in making the most durable fly lines on the planet, but that doesn’t mean they are indestructible. Here are a few things to avoid that will let you get the longest life out of your line:

Casting Without a Leader

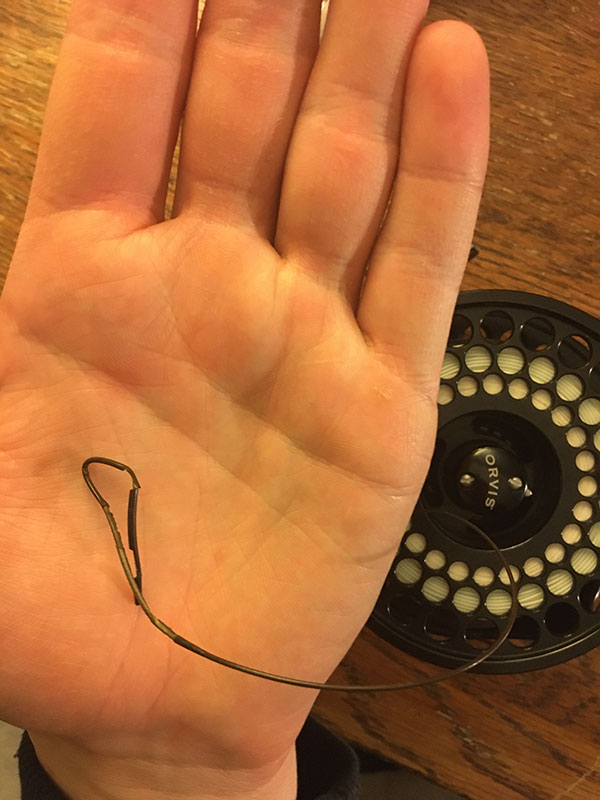

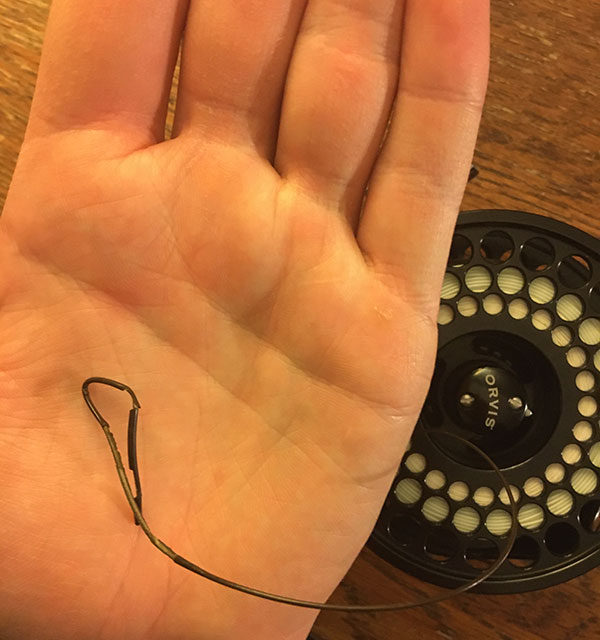

This is a really bad thing to do. Yeah, we get it, you don’t want to trash that $6 leader doing a bit of practice casting, so why not just leave the leader off? Well, you ever the “bullwhip crack” at the end of a cast? That’s the fly line breaking the sound barrier (767 mph) at the end of the forward loop. The line has reached Mach 1! A tremendous amount of force is generated on the loop as the line goes from 700 mph plus to 0 mph in a few milliseconds and can destroy a factory welded loop. The leader acts as a shock absorber for that stress. Adding bit of fluff to the end of a leader also helps reduce shock on the loop.

You can easily make a few 3-piece practice leaders. Knot 3’ of butt section, 3’ midsection, 3’ tippet with a bit of yarn at the end. For most lines, a combination of 20 lb. to 15 lb. to 10lb. works fine. If casting lighter than a 6-wt. drop, reduce these leader weight sections a bit.

Casting on Grass or Asphalt

In the past, grass casting was a common way to practice or try out a rod. However, as lines have gotten more sophisticated this also quickly causes damage to modern fly lines. After just a brief session you’ll notice the line becoming dirty and sticky and likely stress showing at the loop. The features built into the line, such as slickness and texture are negated in a short time.

Casting on asphalt speeds this process even faster with more damage done to a line. Both of these surfaces transfer dirt and grime way faster than water and having increased contact friction, rapidly degrade the line.

Most fly shops have dedicated lines for testing rods that they clean frequently and wear out quickly. If you want to try out a rod with your own line, please try it on water if possible. That way you won’t have issues develop that will negatively affect your fishing and longevity of the line. Always practice casting on water if at all possible. If you need to practice on grass, consider purchasing a line just for that purpose.

Chemical Contact

There are a variety of chemicals that can damage fly lines. Insect repellants, hand lotions, sunscreen, solvents, and others all have the potential to cause problems. Rather than trying to track and list every chemical compound out there, the best advice here is to clean your hands whenever they come in contact with anything questionable. Just a quick wipe on a damp rag can help save your line. If you have had heavy contact with a suspect material, go for thorough soap and water cleaning.

When fishing in an area with bothersome insects, consider a non-chemical repellant. Battery- or fuel-powered ultrasonic tools (like a Thermacell) eliminate the need to handle or touch the repellant and have proven to be highly effective.

Another option is to spray a neck gaiter and sun gloves with permethrin. This gives a double dose of protection- as you minimize UV exposure from the sun as well as keeping the bugs at bay.

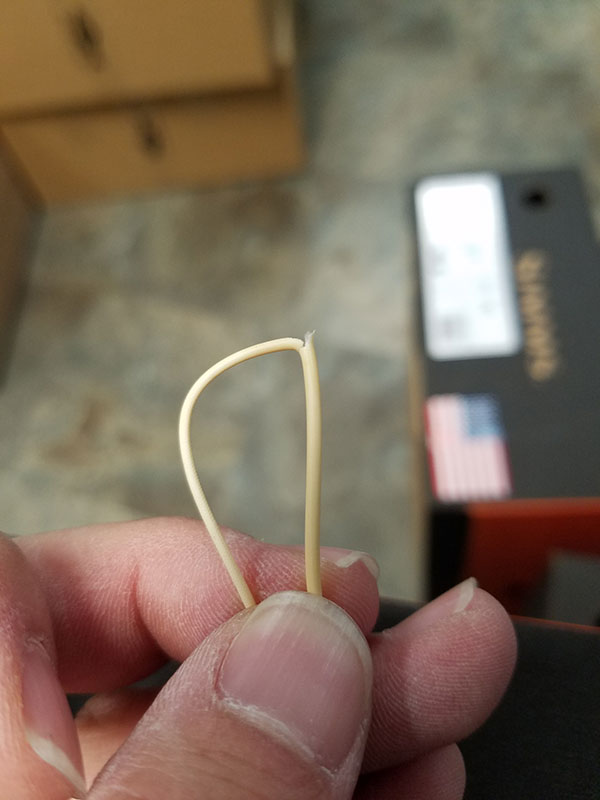

Using the Fly Line to Straighten the Leader

This is another no-no. Leaders come coiled in packaging and take a set in this circular shape. Called “memory”, we want to take this shape out, so the leader will cast and lie generally straight on the water. There are several ways to do this. The first is to stretch the leader. There is a correct and a wrong way to do this. What we DO NOT want to do is grab the fly line just above the welded loop and pull hard on the leader to straighten it. The butt end of the leader is large in diameter and can approach 60 lb. breaking strength. A significant amount of pull is needed to straighten this section and again applying this force can damage the welded loop on the line. A much better option is to hold the loop on the leader and then proceed to pull it straight. You can then work your way down the leader, holding and pulling every 3 feet or so, until you reach the end of the leader.

Summary

Modern fly lines are made to be durable and long-lasting. They have numerous features built into them to maximize both longevity and function on the water. The fly lines made today are much more durable than those of even a decade ago, but they are not indestructible. There are several things that should be avoided to give you fly line a maximum life span.

- Never cast without a leader on the line. The speed and force generated can blow out the welded line loop.

- Avoid casting on grass and asphalt. This damages the coating on the line, the line picks up dirt and grime, and significantly affects performance on the water and reduces the life of the line. The welded loop can also break. Always practice casting on water if possible.

- Avoid any questionable chemicals coming in contact with the line. Clean your hands if necessary to minimize any potential chemical damage.

- Do not straighten the leader by pulling on the line. Instead, hold the leader loop and stretch the leader a section at a time.

Following these simple steps will help maximize the life of your fly line. Combined with a bit of routine maintenance, a fly line can give top performance for a long period of time.

11 Comments

Mark Forster October 07, 2021 - 12:44

Is there a maximum leader diameter recommendation for specific line weights? I fish a 5wt in areas where your bluegill fly can get ambushed by a 5# bass or 7# catfish so I typically run 3x leader/tippet.

S A October 28, 2021 - 15:04 – In reply to: Mark Forster

Mark thanks for the question, you should have no problem stepping up your leader size if you are in an area that has larger bass and catfish, the only thing it may do is limit using flies with smaller hooks sizes with the larger diameter tippet.

Roger December 12, 2021 - 12:07

Interesting! However I practice very often in grass with different lines, and I must say that I have had very few problems, and nothing a cleaning and some dressing couldnt solve…

By the way, why dont you create a practice line!? 🙂

Leland Frankman April 03, 2022 - 19:20

I have many many scientific lines. Just bought an 8 wt Amplitude line.

I have been told not to use line cleaners because your lines are textured, not smooth and the cleaner clogs up the textured lines. What cleaner do you recommend?

S A April 08, 2022 - 15:39 – In reply to: Leland Frankman

Hi Leland we recommend using our Line Cleaner and cleaning pad but not placing on line conditioners as cleaning the line is exposing fresh AST+ that an overcoat conditioner would cover up. Let us know if you have other questions!

sean August 28, 2022 - 21:38 – In reply to: Leland Frankman

do u think a fly getting stuck in a floating flyline will affect its performance in anyway?

S A September 01, 2022 - 12:46 – In reply to: sean

It may if the point of the fly has created a hole down to the core material.

Reese Hunt February 07, 2023 - 18:35

Great info. Most of my fishing buddies are using food grade silicone on the fly lines. My question is this good or bad?

S A March 07, 2023 - 13:22 – In reply to: Reese Hunt

That will not hurt a fly line.

Eddie July 13, 2023 - 15:34

How does heat affect fly line? Would like to keep a “truck rod” stashed under my back seat. It won’t be exposed to light, but the cab can still get hot. I know UV can be brutal on plastic, but will the heat do much more than add a little memory to the line? Typically using tropical/saltwater lines. Thanks!

S A July 13, 2023 - 19:48 – In reply to: Eddie

That shouldn’t be a problem but would let the line cool down slightly if stored in vehicle during a summer day especially if you are using tropical lines.